KUTZTOWN, PA — Palram Americas, a maker of finished and semi-finished extruded thermoplastic sheet products and panel systems experienced repeated failure of sweep elbows in pneumatic conveying lines due to abrasive wear. Project Manager Joe Obrien says PVC resin striking the inside walls of the system’s 4 ft (1.2 m) long, 14-gauge stainless steel sweeps created pinholes that required patching or replacement after just five months of service.

The plant operates 24/7, so replacing failed elbows incurred two- to four-hour shutdowns per incident, as well as parts and labor costs.

“We considered installing thicker-walled sweeps, and other companies offered to reinforce the affected sections of the line,” Obrien said, but after doing some research, Palram installed HammerTek deflection elbows on its two lines conveying PVC from silos to dosing systems. Each line required a pair of new 90-degree elbows, with two at the top of a 16 ft (4.8 m) vertical run, and the two at the start of a 60 to 80 ft (18.3 to 24.4 m) horizontal run to the dosing system. He notes that the pressure differential in the pneumatic conveying system was not adversely affected by the switch to the deflection elbows, so no adjustments were required to other system parameters.

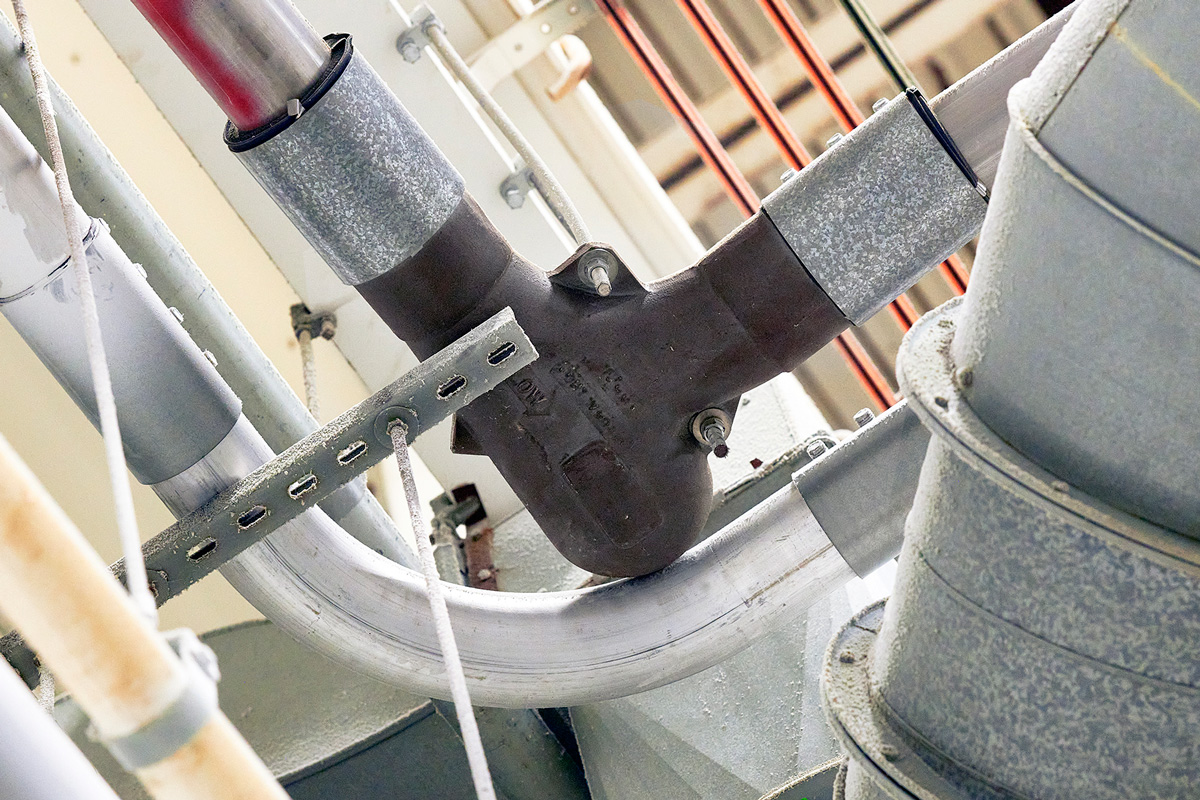

HammerTek’s Smart Elbow® design features a spherical vortex chamber protruding slightly beyond the desired pathway. When material transitions into the elbow, part of the flow is diverted into the vortex chamber, where it forms a loosely packed ball of material that rotates slowly in the direction of the airstream that powers it, gently deflecting incoming particles around the bend without impacting the elbow wall.

The deflection elbows cost more than standard stainless-steel sweeps, Obrien acknowledges, but they have already paid for themselves. After two years of use, he says the Smart Elbow units have been maintenance-free.

“It’s a success story for us,” Obrien says, adding that Palram will look to replace any sweeps on its polycarbonate lines if they also show signs of wear.

In business for more than 50 years, Palram, a subsidiary of Israel-based Palram Industries Ltd., says it “continually pushes the limits of thermoplastic technology to solve emerging market challenges.” Today, the company’s PVC and polycarbonate products are used in countless applications worldwide — from stadiums and airports to agricultural facilities, commercial buildings, and private residences.

Palram Americas

9735 Commerce Circle

Arcadia West Industrial Park

Kutztown, PA 19530

610-285-9918

ContactUs.USA@palram.com

www.palram.com